How Modern Fleets Maximize Fuel Efficiency: Real-World Insights for Today’s Drivers and Managers

Introduction

Fuel costs remain one of the largest operating expenses for any fleet, and even small gains in efficiency translate into meaningful savings over thousands of miles. At The Service Company, we work directly with drivers and fleet managers who want practical answers—not vague industry jargon. Here’s a clear, real-world breakdown of what actually drives better fuel economy in today’s diesel trucks.

Understanding Fuel Tank Capacity Across OEMs

Most long-haul trucks from top OEM brands, such asPeterbilt, Kenworth, Volvo, and Freightliner, carry 120 to 150 gallons per tank, often configured as dual tanks for a total of 240 to 300 gallons.

This common range balances two priorities:

• Maximizing time between fuel stops

• Avoiding unnecessary weight penalties from carrying excess fuel

For fleets, properly matching tank capacity to the types of routes you run can eliminate wasted time and reduce operating stress. Our technicians regularly help drivers evaluate whether their tank setup aligns with their mileage demands.

Fuel tank capacity

Which OEMs Deliver the Best Real-World Fuel Economy?

While tank size determines range, it’s fuel efficiency that determines cost per mile.

Based on real-world data from the American Transportation Research Institute (ATRI):

• Volvo and Freightliner often deliver 8.5–10 MPG in optimized highway use

• Kenworth and Peterbilt typically fall between 7.5–9 MPG, depending on configuration, driving habits, and load

The differences are subtle—what matters most is how consistently the truck stays within its efficient RPM band, maintains steady speed, and minimizes aerodynamic drag.

Across our customer base, we regularly see 1–2 MPG gains simply by improving airflow around the tractor and trailer or optimizing cruise-control behavior.

Fuel efficiency

Automated vs. Manual Transmissions: Why AMTs Win

The shift to automated manual transmissions (AMTs) has reshaped long-haul performance. AMTs outperform traditional manuals because they optimize each gear shift based on:

• Torque demand

• RPM

• Load weight

• Terrain grade

Fleets transitioning from manual to AMT routinely see 1–2 MPG improvements, with even greater gains when paired with predictive cruise systems.

Even the most skilled manual drivers struggle to match the consistency of an AMT. Drivers tell us the same thing time and again: AMTs cut fatigue, improve uphill pulls, and reduce fuel burn during shifting. It’s why they’ve become standard equipment on today’s long-haul tractors.

The Truth About Emissions-Compliant Engines

Many still believe pre-emissions engines outperform modern engines in fuel economy. In reality, the opposite is true.

Early emissions systems from the mid-2000s did create efficiency setbacks. Those first-generation EGR and DPF systems were restrictive, regen-heavy, and often cost fleets fuel. But today’s aftertreatment and combustion technologies have completely changed the landscape. Independent research from the International Council on Clean Transportation shows that modern soot-free heavy-duty diesel engines burn cleaner and operate more efficiently than older pre-EPA engines, thanks to advances in injection, air handling, and aftertreatment design (ICCT, 2020).

Modern diesel platforms from Volvo, PACCAR, Cummins, and Detroit Diesel are now built to:

• Burn cleaner through high-pressure common-rail injection and optimized aftertreatment

• Run leaner with advanced turbocharging and precise electronic fueling

• Maintain ideal combustion temperatures more consistently under load

These improvements directly translate to better real-world fuel economy. Studies of the newest diesel-powered vehicles confirm measurable gains in both fuel efficiency and CO₂ reduction compared with earlier-generation diesels, even before factoring in the cleaner combustion benefits (Frontiers in Mechanical Engineering, 2019). The U.S. Department of Energy also notes that modern diesels achieve significantly higher energy efficiency due to these same advancements.

Cleaner combustion also reduces soot loading, which means fewer regens, less downtime, and far more stable long-term performance—especially when fleets follow proper maintenance schedules. Cummins reports that pairing modern combustion strategies with updated aftertreatment allows engines to maintain high fuel efficiency while dramatically reducing emissions and minimizing regen cycles.

In short, while early emissions technology temporarily set the industry back, today’s diesel engines are cleaner, leaner, and more efficient than the pre-emissions platforms many still romanticize. When maintained correctly, modern diesel engines consistently outperform older engines in MPG, durability, and emissions control.

The Real-World Variables That Shape MPG

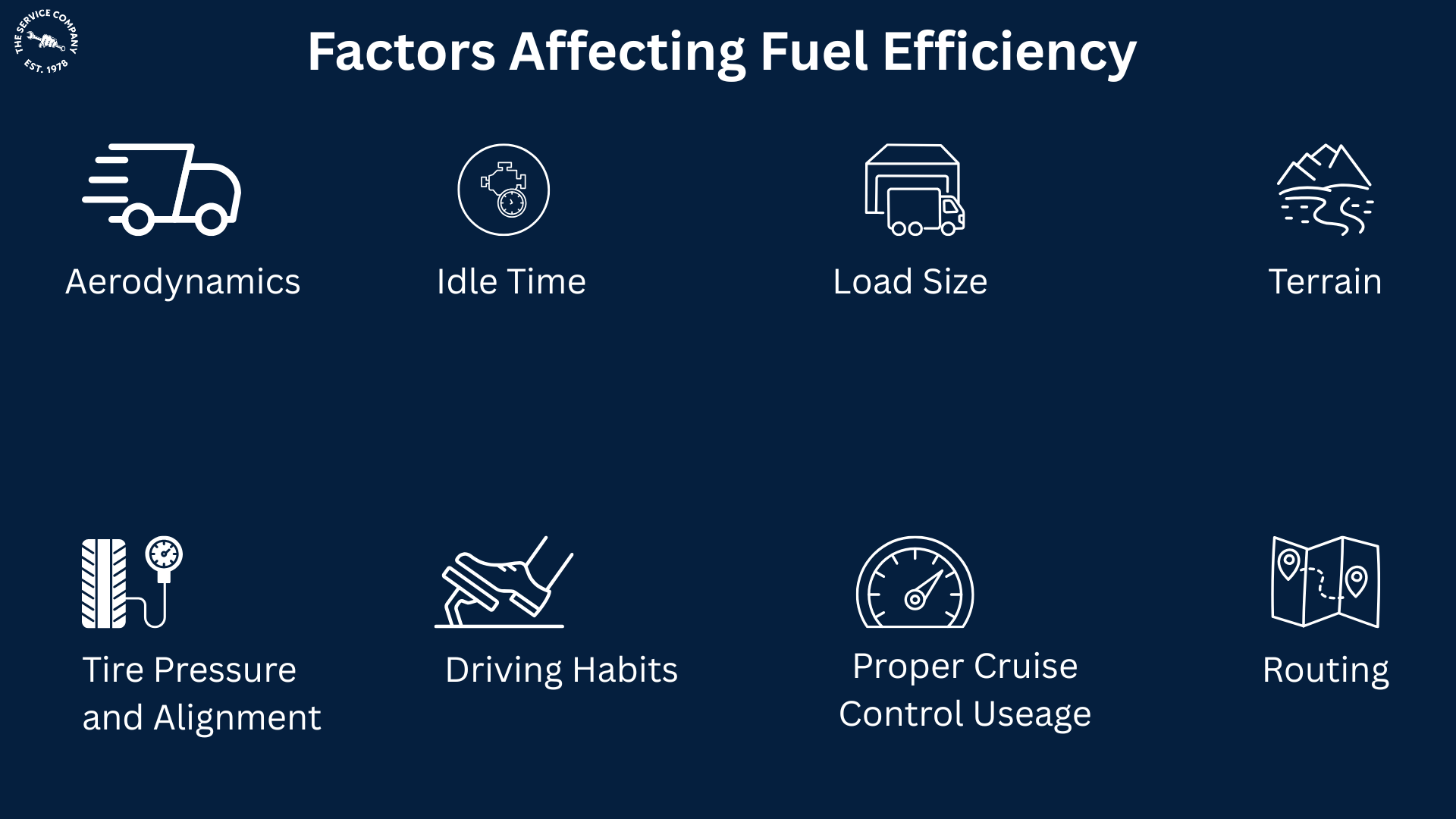

Fuel efficiency is influenced by far more than the badge on the hood. Major MPG factors include:

• Aerodynamics

• Tire pressure and alignment

• Idle time

• Driving habits

• Load weight

• Route terrain

Industry data shows aerodynamic upgrades, roof fairings, side skirts, trailer tails, can improve MPG by 10–15%. Reducing aggressive acceleration and idle time can add another 20% improvement.

At The Service Company, we emphasize a holistic approach. With proper alignment, optimized tire conditions, correct inflation, and consistent engine performance, a truck running at 6.5–8 MPG can often be brought into the 9–10+ MPG range over time.

Different factors affecting fuel efficiency in the real world

Conclusion: Fuel Efficiency Comes From a System, Not a Single Feature

Every component, engine type, OEM design, transmission choice, aerodynamic setup, and driver behavior plays a role in determining real-world fuel economy.

Most modern trucks from Peterbilt, Kenworth, Volvo, and Freightliner are capable of excellent MPG when maintained and operated correctly. AMTs, improved emissions systems, and aerodynamic advancements have all contributed to meaningful gains.

If you’re looking to improve fuel efficiency or benchmark your fleet against modern averages, The Service Company is ready to help. Our technicians work every day to reduce fuel burn, extend component life, and make each mile more profitable for fleets across the region.